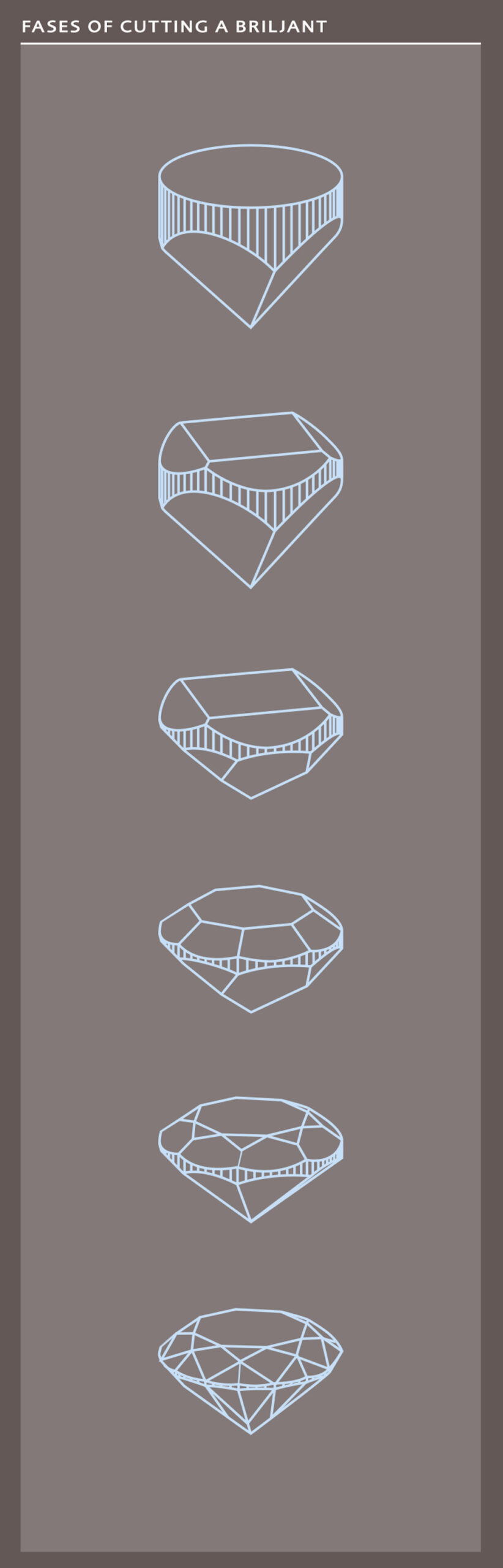

In order to make a sparkling stone from a rough diamond, processing is necessary. This must be done very carefully because if mistakes are made, the stone can disintegrate into small fragments or even burn up.

The most important steps of the processing are: cleaving or sawing, bruting and polishing. Because diamonds are composed of layers, they can be split (cleaved). When faceting the diamond, one must take account of the ‘grain’, the direction in which the crystals have grown.

In Venice, at the beginning of the 14th century, diamonds were cut for the first time. In the 17th century, Amsterdam became the world center for the processing of, and trade in, diamonds. Today, the main polishing centers are: Antwerp, Mumbay, Surat, Guangzhou, Tel Aviv and New York.

Cleaving

Cleaving (splitting) diamonds demands great knowledge on the part of the cleaver.The position where the stone is to be cloven or sawn is first marked with ink. Afterwards, the cleaver fixes the diamond to a cleaver’s stick with the aid of cleaver’s cement and, with another diamond, makes a V-shaped groove at the spot where the stone is to be cloven. He puts the blunt cleaving knife in the groove and gives a short blow with the mallet there. Then the diamond splits in two. The technique of cleaving is no longer practised very much. It has been largely replaced by sawing, or, with larger diamonds, by cutting with the aid of a laser beam.

Sawing

For sawing diamonds, a thin sawing disc (0.05 to 0.14 mm thick) made of phosphor bronze is used, the edge of which is coated with a mixture of diamond powder and oil. The stone is sawn at 4500 to 6500 revolutions per minute.

Bruting

The still uncut shape can be rounded by grinding the diamond against another diamond (the ‘polisher’). The grindings are retrieved and used for industrial purposes.

Polishing

Now the facts must be introduced that allow the diamond to sparkle. This used to be done by fixing the stone in a lead dop (cap), which was clamped into a wooden tang (tongs) with a copper handle. The precise placing of the diamond in the dop was the work of the ‘setter’. Nowadays, the polisher puts the stone into the polishing tang directly. The facets are polished on the stone with a horizontally-revolving polishing scaife (wheel) coated with oil and diamond powder. The stone sometimes loses up to 70% of its weight due to the polishing process.

Cut

For centuries in some cultures, cutting as large a stone as possible out of rough material was paramount; a precisely symmetrical shape was less important. This is called India or Ceylon cut. It is however, very important for diamonds that the facets be cut precisely symmetrical, because then the light can be collected and reflected from all directions. In this way, optimum sparkle and brilliance can be achieved. Due to modern polishing equipment there are hardly any limitations in cutting shapes

| Cookie | Duration | Description |

|---|---|---|

| __cfduid | 1 month | The cookie is used by cdn services like CloudFare to identify individual clients behind a shared IP address and apply security settings on a per-client basis. It does not correspond to any user ID in the web application and does not store any personally identifiable information. |

| _GRECAPTCHA | 5 months 27 days | This cookie is set by Google. In addition to certain standard Google cookies, reCAPTCHA sets a necessary cookie (_GRECAPTCHA) when executed for the purpose of providing its risk analysis. |

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-advertisement | 1 year | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Advertisement". |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| csrftoken | 1 year | This cookie is associated with Django web development platform for python. Used to help protect the website against Cross-Site Request Forgery attacks |

| elementor | never | This cookie is used by the website's WordPress theme. It allows the website owner to implement or change the website's content in real-time. |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |

| Cookie | Duration | Description |

|---|---|---|

| _ga | 2 years | This cookie is installed by Google Analytics. The cookie is used to calculate visitor, session, campaign data and keep track of site usage for the site's analytics report. The cookies store information anonymously and assign a randomly generated number to identify unique visitors. |

| _gat_gtag_UA_167950907_1 | 1 minute | This cookie is set by Google and is used to distinguish users. |

| _gid | 1 day | This cookie is installed by Google Analytics. The cookie is used to store information of how visitors use a website and helps in creating an analytics report of how the website is doing. The data collected including the number visitors, the source where they have come from, and the pages visted in an anonymous form. |

| _hjFirstSeen | 30 minutes | This is set by Hotjar to identify a new user’s first session. It stores a true/false value, indicating whether this was the first time Hotjar saw this user. It is used by Recording filters to identify new user sessions. |

| Cookie | Duration | Description |

|---|---|---|

| _fbp | 3 months | This cookie is set by Facebook to deliver advertisement when they are on Facebook or a digital platform powered by Facebook advertising after visiting this website. |

| fr | 3 months | The cookie is set by Facebook to show relevant advertisments to the users and measure and improve the advertisements. The cookie also tracks the behavior of the user across the web on sites that have Facebook pixel or Facebook social plugin. |

| Cookie | Duration | Description |

|---|---|---|

| _hjAbsoluteSessionInProgress | 30 minutes | No description |

| _hjid | 1 year | This cookie is set by Hotjar. This cookie is set when the customer first lands on a page with the Hotjar script. It is used to persist the random user ID, unique to that site on the browser. This ensures that behavior in subsequent visits to the same site will be attributed to the same user ID. |

| _hjIncludedInPageviewSample | 2 minutes | No description |

| _hjTLDTest | session | No description |